HOME

PRODUCTS

INDUSTRY INFO

DOWNLOAD

CUSTOMER CASE

SERVICE

COMPANY

CONTACT US

Handheld Inkjet Printers

Portable Inkjet Printers

Small Character Inkjet Printers

Large Character Inkjet Printers

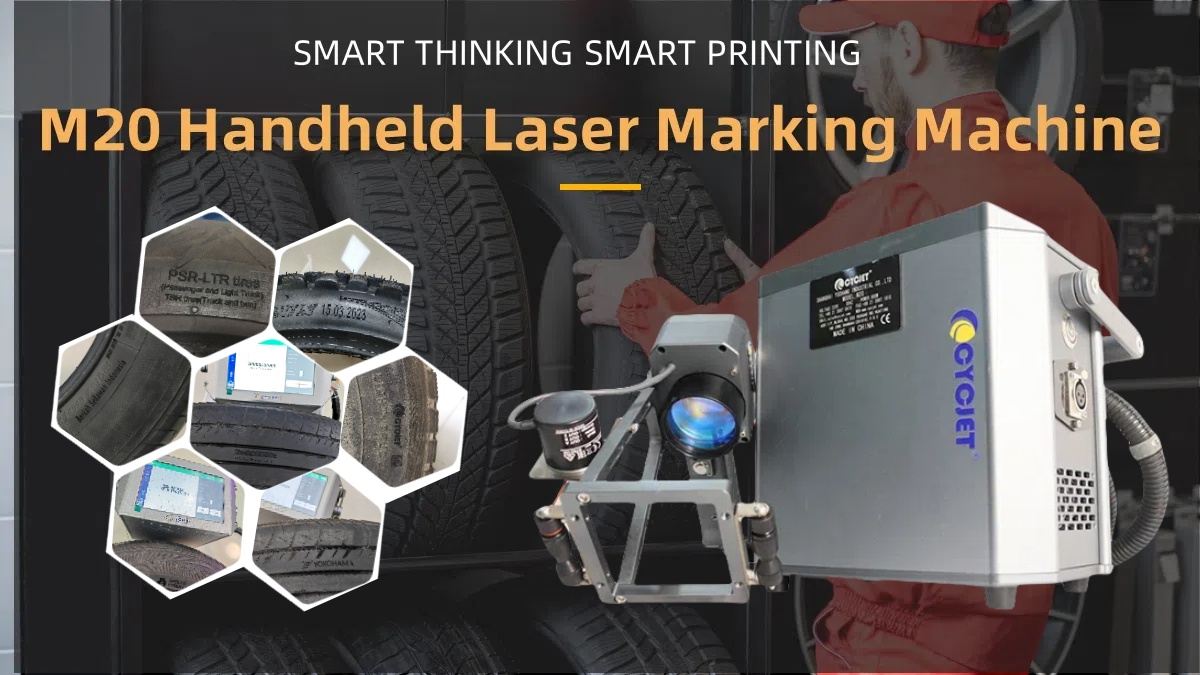

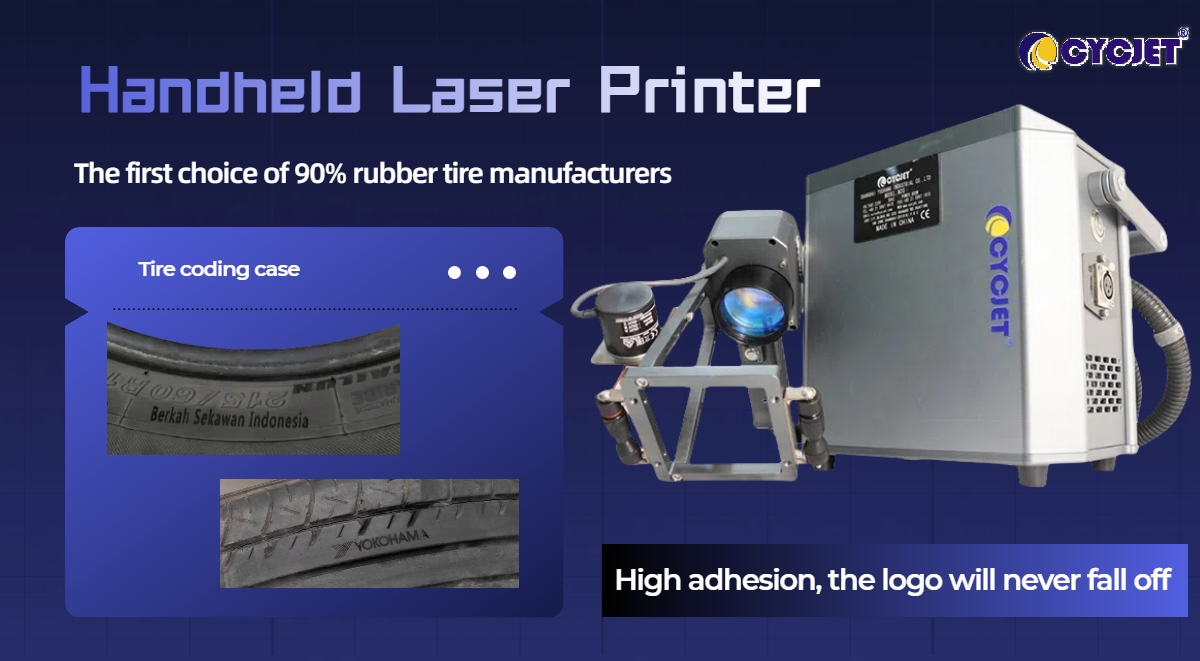

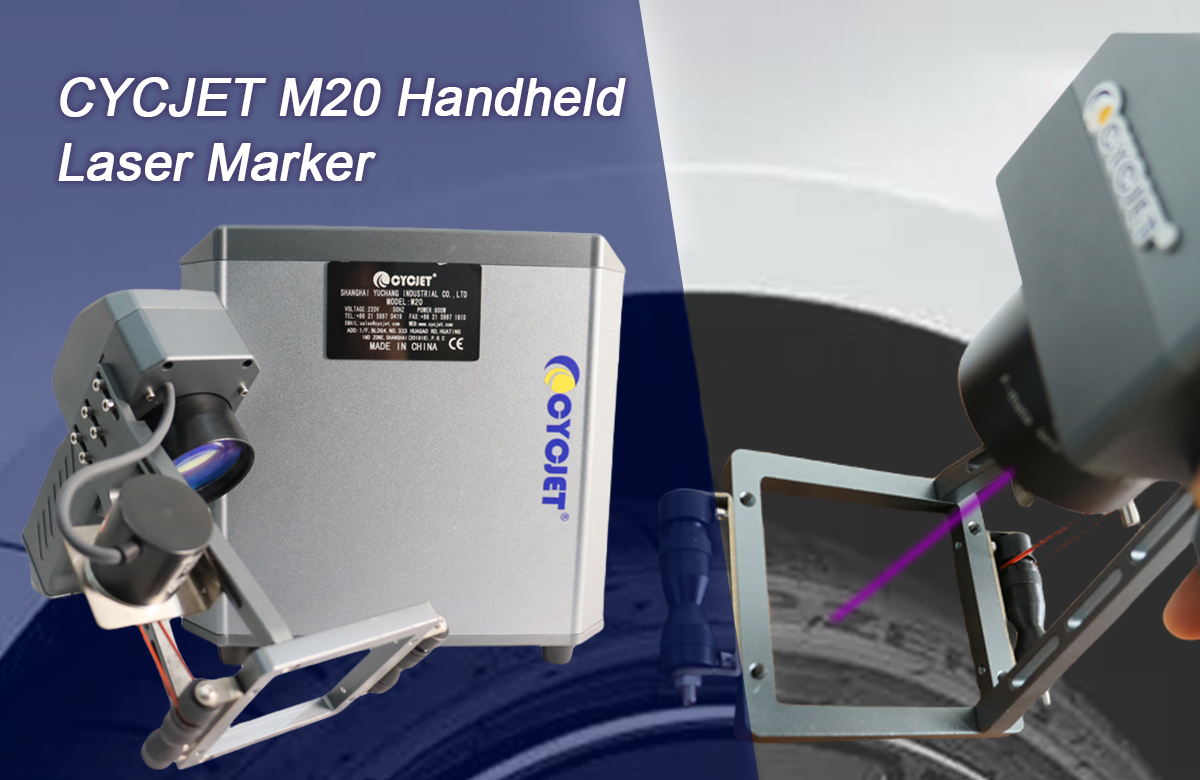

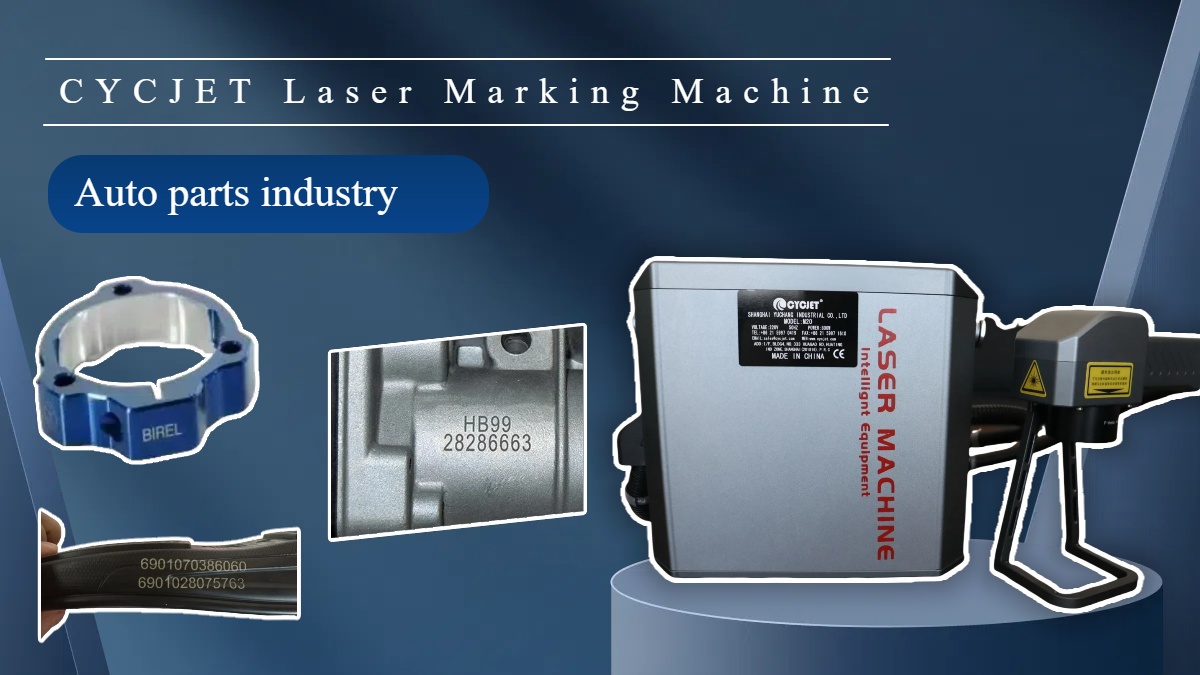

Handheld Laser Markers

High Speed Fly Laser Printers

Static Laser Marking Machines