Laser coding solution for sterile dairy product containers

2020-04-20source:access:4748

Laser coding machines are often used to print clean and clear product codes in harsh dairy production environments. Laser printers can help dairy producers extend uptime, reduce maintenance requirements, and improve logo readability. Using CYCJET laser solutions can meet the requirements for more accurate, clear and durable product coding.

Challenges facing the dairy industry:

It is expected that by 2026, the use of aseptic packaging, including new and improved consumer-friendly packaging, will continue to grow at a rate of 12%. Dairy producers use aseptic packaging to maintain the freshness, taste and nutritional quality of dairy products to meet the increasing expectations of consumers. Although the shelf life of aseptically packaged products is longer, which can expand the scope of product distribution, it is a challenge to code on this multi-layered, brightly coated material, especially in low-temperature production environments.

Advantages of CYCJET Fly Laser Printer:

CYCJET laser coding system can be customized according to your needs and applications, and the coding speed can reach 900 meters / minute. CYCJET high-performance CO2 laser coding machine can provide clear and durable coding on various types of dairy products including aseptic packaging.

Optional CYCJET LF series laser coding machine controller is designed to reduce operation errors and ensure consistent and accurate product coding. In addition, optional productivity tools are available to help you determine the root cause of downtime incidents, thereby helping you continuously improve your processes.

Advantages of laser marking machine:

Laser coding technology can provide highly clear and durable coding on the packaging. In addition, the laser printer does not require ink and consumables, which simplifies production and reduces the total cost of ownership.

Integrated:

Due to the production characteristics of the filling equipment, most sterile containers are marked on the conveyor system after the filling and sealing procedures are completed. In the rinsing environment, the laser printer with IP65 protection level does not need to move the position during the rinsing process, which can save time and cost. You can also choose a laser coding machine with IP65 protection to avoid potential damage caused by dairy products or water entering the coding machineduring packaging or rinsing.

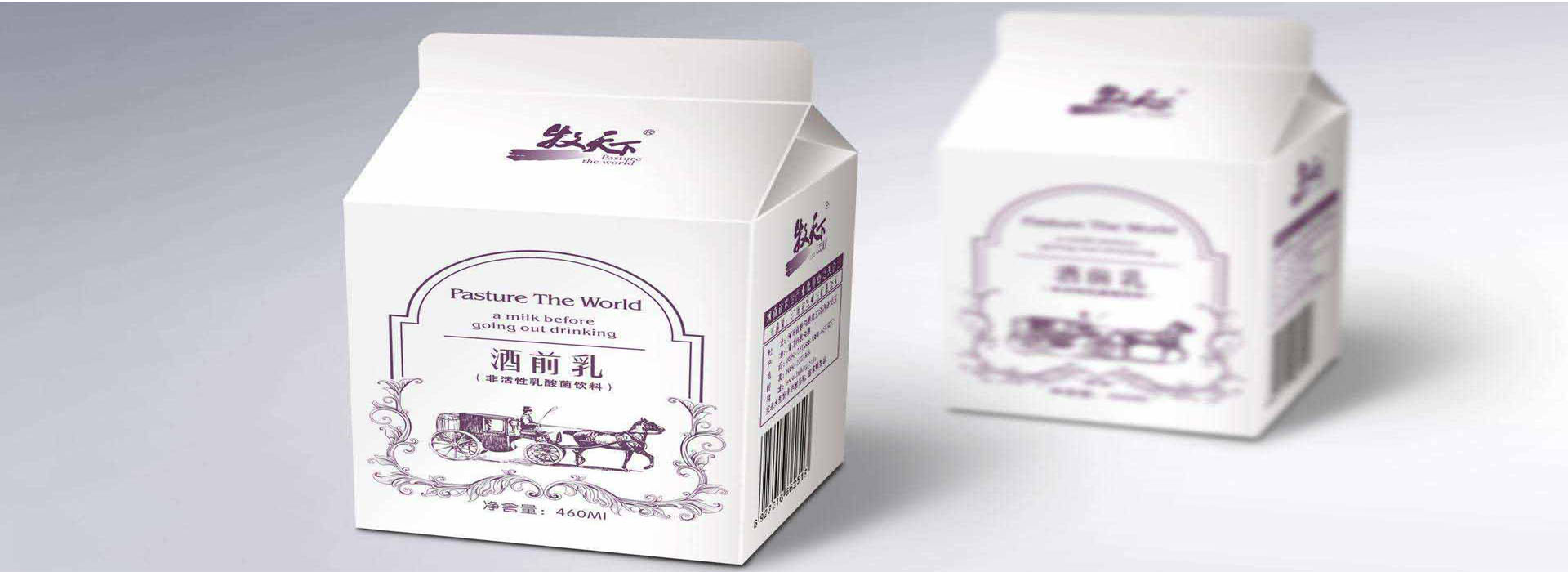

Mark directly on the container:

Laser marking by burning. This process etches a small amount of ink from the outermost ink layer preprinted on the surface of the box. When choosing a laser solution, you should consider lens requirements, docking, and laser wavelength. The end result is to create an appropriate line thickness logo with the minimum energy required. Because small configuration differences can cause huge performance differences, creating the best logo on a given material requires that the laser solution must be configurable.

Laser sensitive marking:

For light-colored aseptic packaging, another method of marking is to add laser-sensitive pigments to the top coating ink during the production of the packaging. This kind of paint is usually applied to a small area you want to mark. The laser energy interacts with the pigment to change the color, so that a clear, durable, and durable code is printed.

CYCJET is a brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than ten years’ experience for wholesaler and retailer of different types ofhandheld inkjet printing solution, Laser printing solution, portable marking solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707(whatsapp)

Email: sales@cycjet.com

Web: www.cycjet.com

Reference video:

1. https://youtu.be/xELriTsinUE

2. https://youtu.be/COhPwdnxSsk

3. https://youtu.be/hCcCkoF75qU

4. https://youtu.be/ooOaS4CKhAs